ALPIlignum is the base element of production at ALPI. Assiduous research and development combined with technological innovation and artisanship have resulted in a reconstituted wood that is the heart and symbol of the ALPI universe. Made of real wood, ALPIlignum is a non-printed, designable product made by disassembling and reassembling the raw material in infinite ways, creating a limitless number of wood types, finishes and patterns for veneer – a fascinating and complex procedure that requires inventiveness and skilled craftsmanship in equal amounts.

Peeling, dyeing, recomposing, glueing, pressing, squaring, cutting and testing form the production sequence of ALPILignum, through which the company creates its woods, offering different and novel textural effects inspired by the world of nature and that of design par excellence. A precise design approach that hones every phase to transform the material, surpassing conventional parameters of development to achieve true Wood by Design.

Thanks to its in-depth research and industrial culture, ALPI is, therefore, able to offer bespoke wood at the service of design, enhancing the intrinsic characteristics to respond to all project needs, and providing custom solutions and unlimited aesthetic variety.

ALPIlignum veneer is also available in the ALPIlignum Paper Back version combining the aesthetic characteristics of wood with a high level of flexibility made possible by the special support sheet, 10 mil paper, generating a product that is particularly suitable for soft forming. ALPIlignum Paper Back permits very narrow curvature radii while reducing scrap, and it is easy to stain or finish. These characteristics make it ideal for laminating to curved or flat surfaces or the creation of edge banding.

Other available backings

-20 mil paper

-Polyflex

-Pressure sensitive adhesive

—

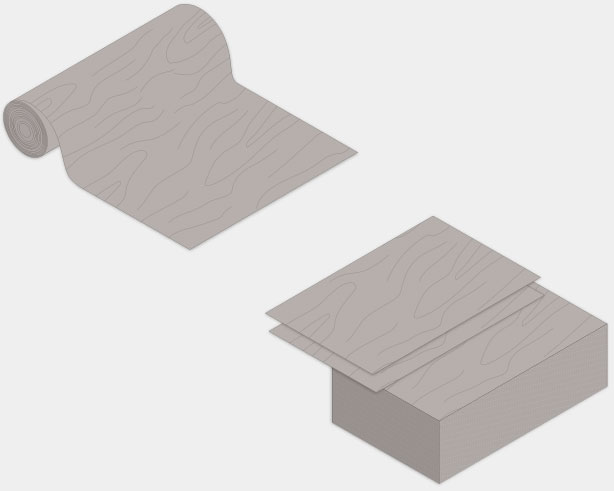

The trunk is peeled.

Thin sheets of wood, all the same size.

—

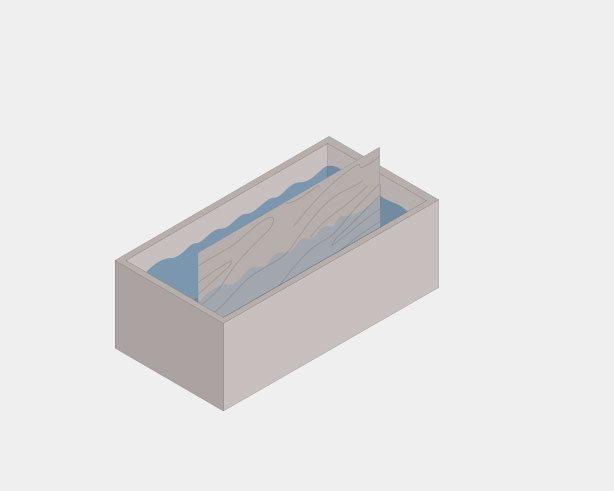

The wood sheets are dyed.

Final color of wood is defined.

—

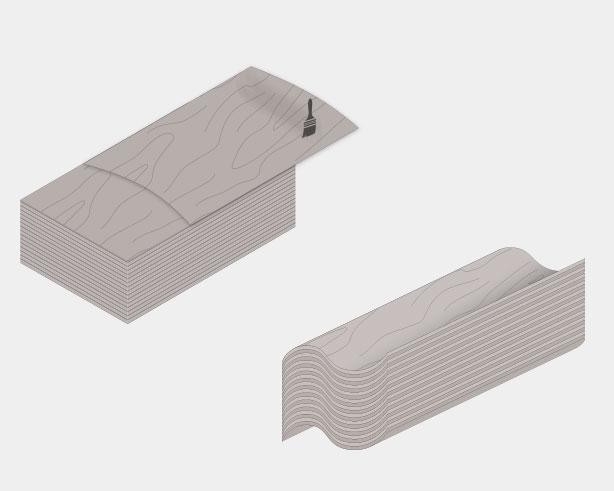

The wood sheets are glued together to create the ALPI trunk.

The trunk is shaped in curved molds to determine the wood grain.

—

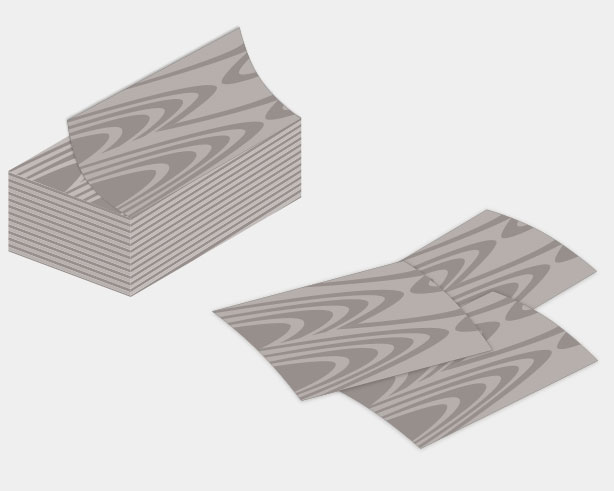

The original trunk is disassembled and reassembled in order to define the final wood grain and colors according to the designer needs.

—

The new ALPIlignum trunk is cut into decorative wood sheets.

Uniform sheets for color, grain and dimension.

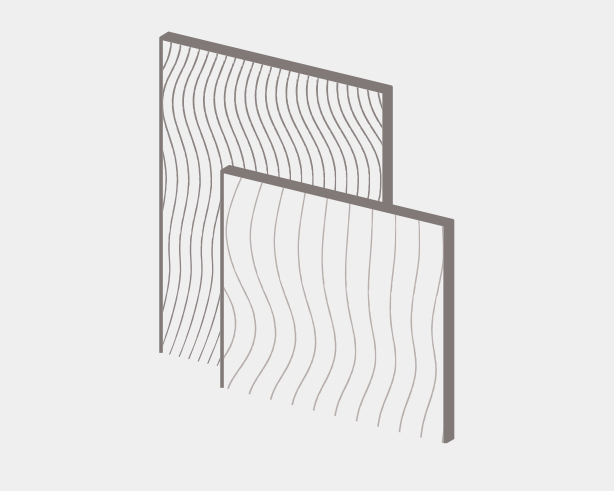

ALPIready is a decorative surface in prefinished wood, ready for use, made of two layers of ALPIlignum joined by adhesive film. ALPIready is finished on the front side.

The product is durable, flexible and easy to use. ALPIready shortens the time and effort spent on panel fabrication and installation. ALPI has chosen the most suitable finishes formulated to beautify the naturalness and color of the wood. ALPI also produces matching edge banding for each pattern. In line with the company's sustainable approach, ALPIready is made with wood from responsibly managed forests certified by the FSC® (FSC® C084497).

Each pattern is finished in one of the following types of finish, formulated to exalt the aesthetics of the wood grain. TOUCH: Maintains the naturalness of the wood while being soft and pleasant to the touch. GROOVE: Emphasizes the grain and textural quality while being like raw wood to the touch. WAX: A matte finish rendering the delicate appearance of wax-treated wood. OIL: A finish that enlivens the color of the wood while giving it the typical sheen of natural-oil treatments.

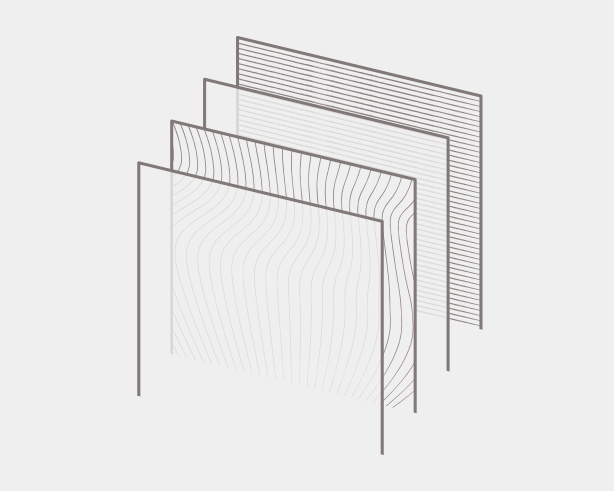

—

1. Finish

2. ALPIlignum wood veneer

3. Adhesive

4. ALPIlignum wood veneer

—

A. 4’x10’

B. 4’x8’

—

Matching prefinished Edgebanding is available.

Web Design, Art Direction and Web Programming / FRI-WEB; The pictures are protected by the law of copyright and it is illegal to use them without a written permission.